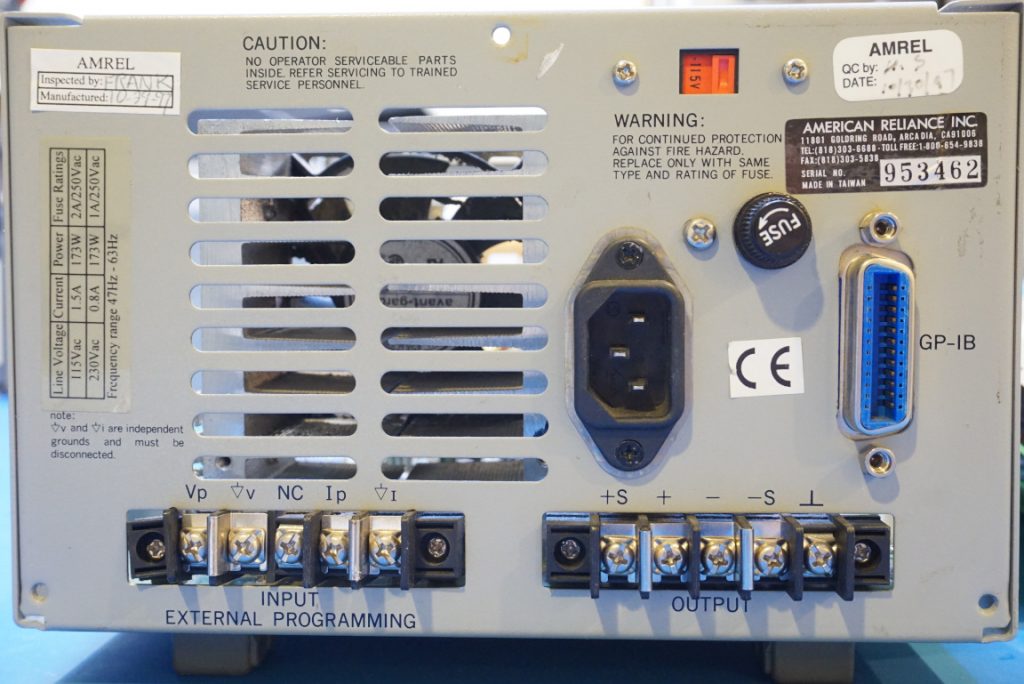

A while back, I did a teardown on a dual-channel Amrel PPS-2322 programmable power supply, and was quite impressed by its solid construction. Recently, I found another Amrel power supply on eBay and this time it is a single channel version (PPS 35-2). Let’s take a look inside this signal channel version and see how much in common it has compared to the dual channel 2322.

The single channel version of the Amrel programmable power supply has front panel sensing terminals making it handy for remote sensing applications. Although the dual channel version has remote sensing capability as well it is only available through wiring at the rear terminal block so it is less convenient.

Although the PPS 35-2 is only rated at half of the total power dissipation (35V, 2A single channel) compared to the 2322 (35V, 2A dual channel), they weigh just about the same. So it would be curious to see what the difference are inside.

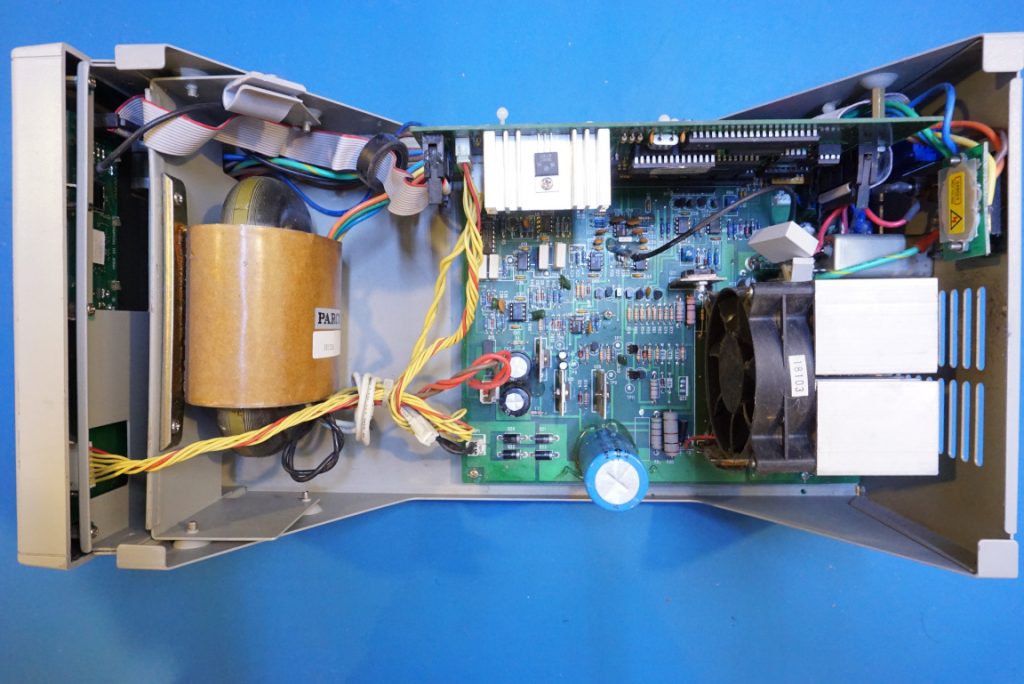

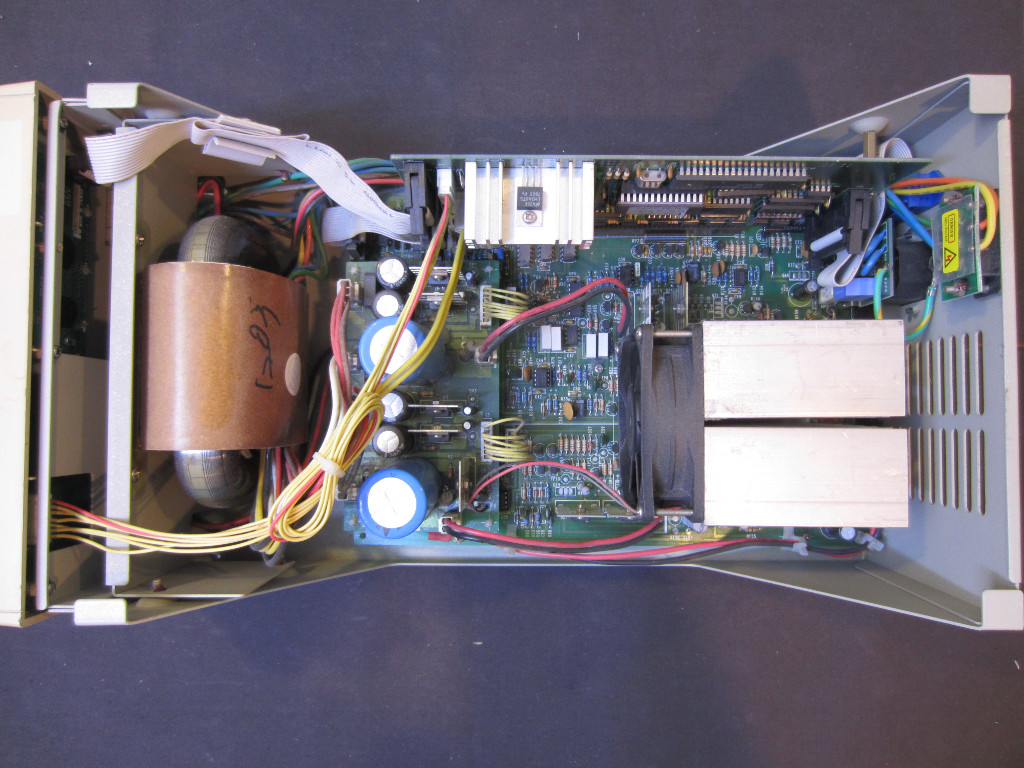

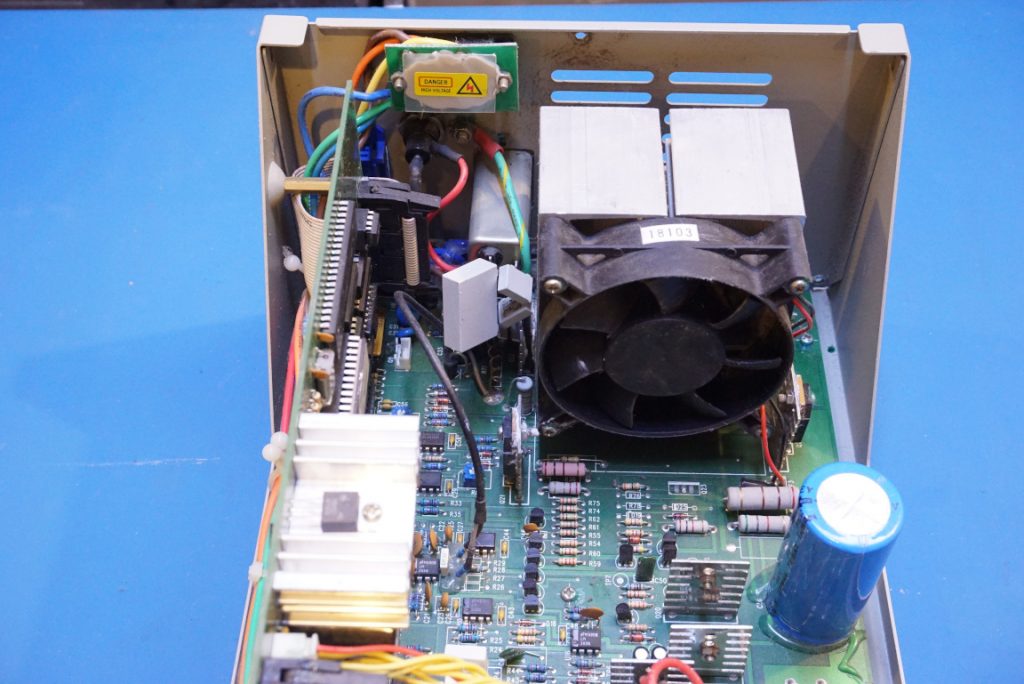

The following are a couple of pictures of the insides of both the PPS 35-2 (left) and the dual channel PPS 2322 (right). As you can see the layout is almost identical. The only obvious difference is the auxiliary power supply riser board and the slightly larger heatsink in the PPS 2322. Both power supplies use the same size toroidal core which explains why the PPS 35-2 is only marginally lighter than its dual-channel cousin.

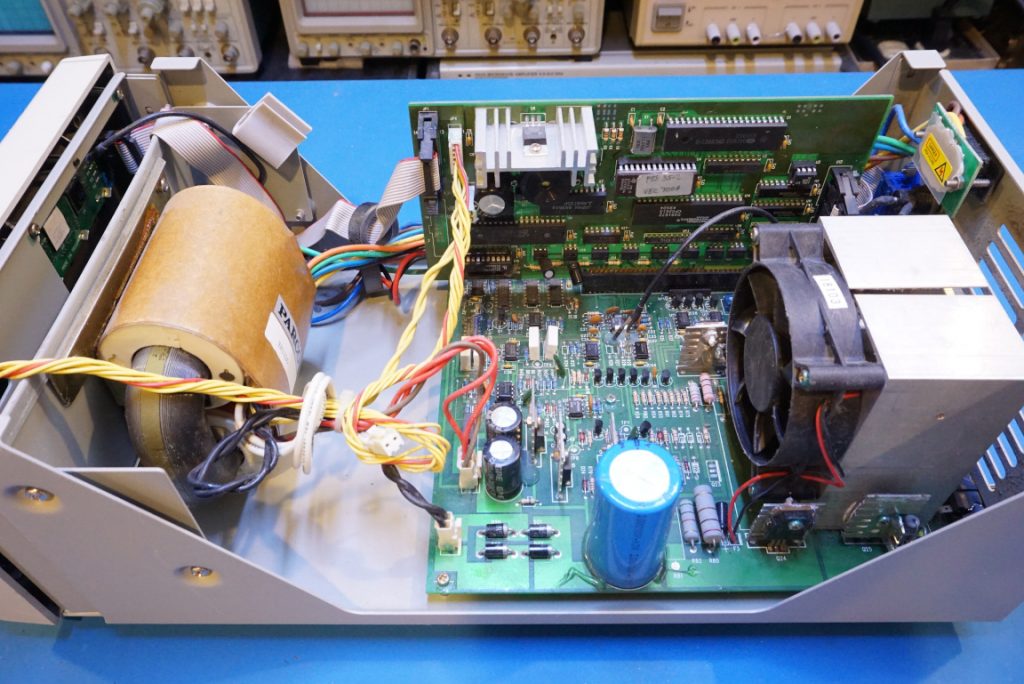

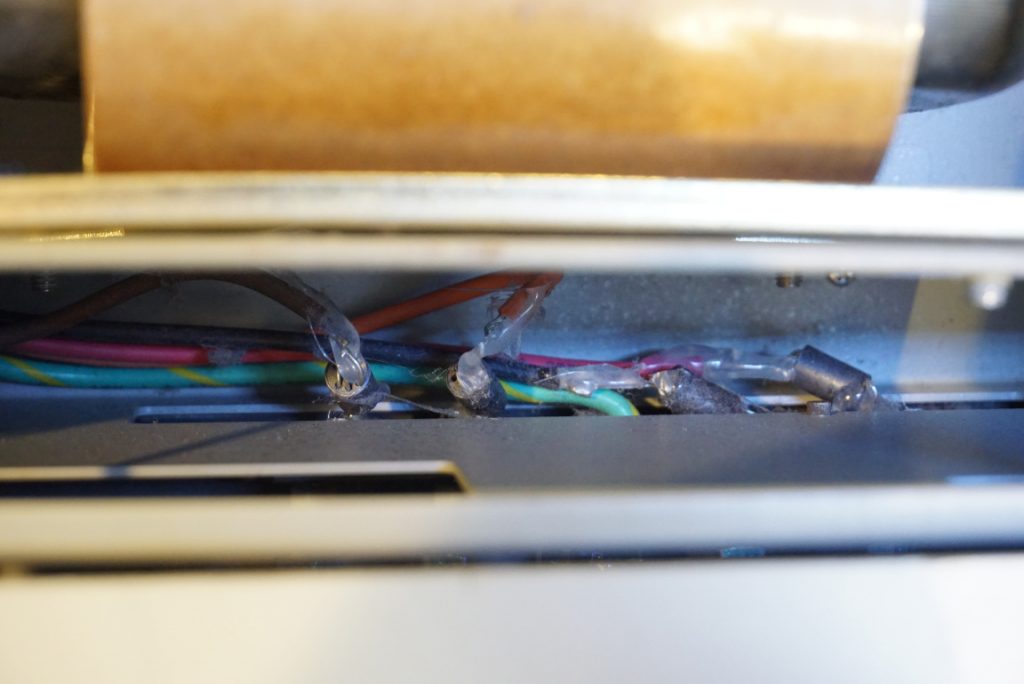

Here are a couple more pictures of the inside of PPS 35-2 from different angles. Compared to the 2322, the capacitors mounted on the power entry module does not look as well thought out. Instead of being mounted on a separate PCB like in the 2322, the capacitors were simply soldered on the power entry module socket.

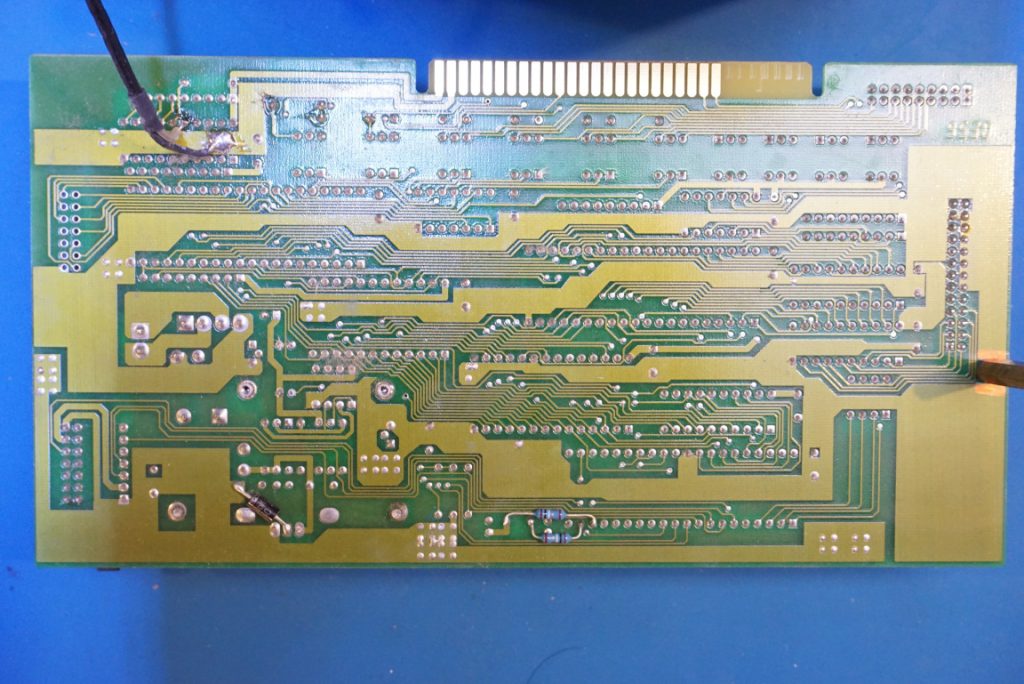

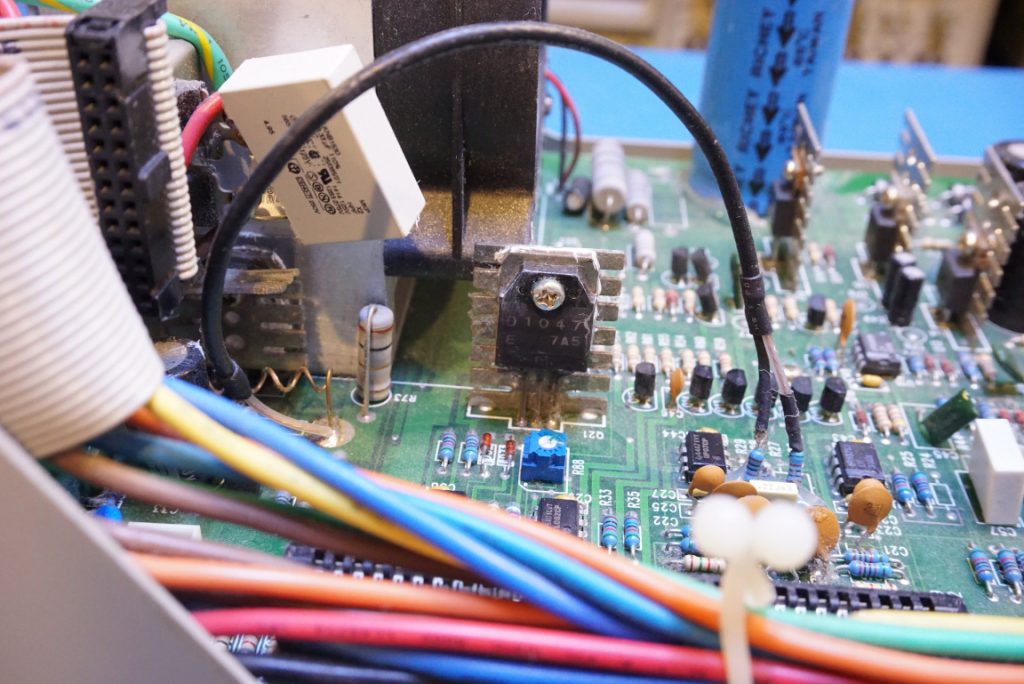

The pictures below are the digital controller/processor board. The board itself is virtually identical to the one found in the dual-channel version. The only visible differences are the un-populated footprint of a connector presumably reserved for the dual channel version and a few bodged on components on both sides of the PCB. There is also a wire on the back of the PCB carrying signal to the front panel which is abscent on dual channel version.

Clearly, this board’s design is shared between both the single channel and the dual channel versions of the power supply. Like the controller board found in the PPS 2322, the processor board contains a CPLD (GAL16V8B) chip, two SRAM chips (MPM81C55P-2 is a 2K SRAM and M58725P is a 16K SRAM), and a 80C31 microprocessor (DMC60C31E, which is essentially a ROM-less 8051). The NI chip (CP02613) is presumably the GPIB controller (although I could not find any information on this chip). The firmware is stored in the UV-erasable EPROM (the firmware version of my unit is 7.00B).

The content of the EPROM can be downloaded towards the end of this post in case you need it.

From the datecodes on the components, we can deduce the manufacturing date to be sometime in the late 1996 or early 1997. This unit is likely slightly newer than the dual channel PPS 2322 I have.

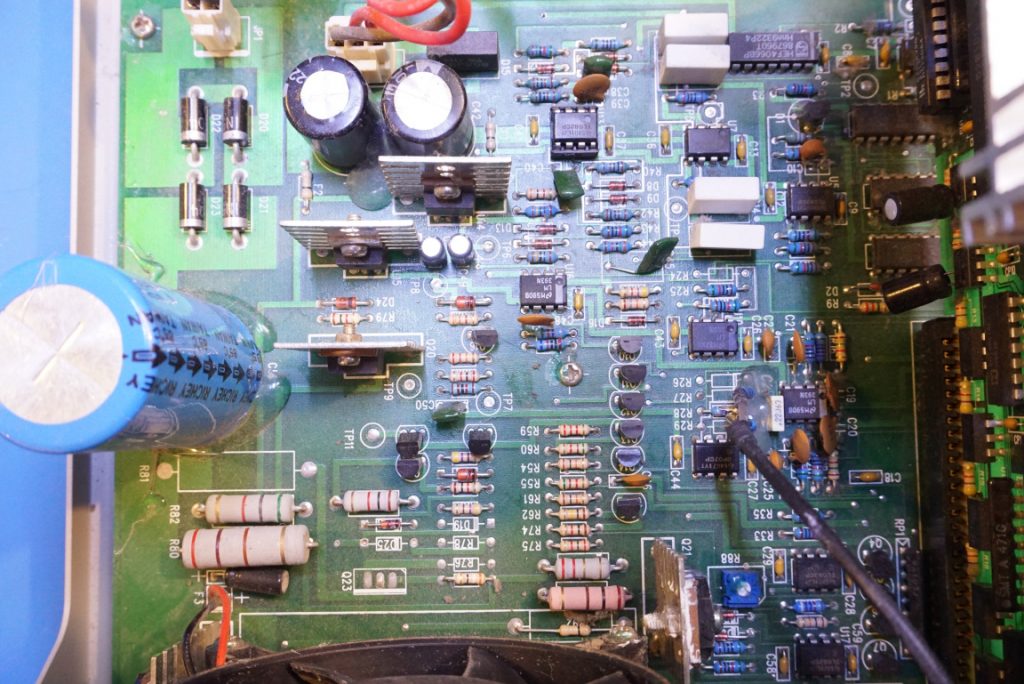

Here are a couple of pictures of the main board. Because the PPS 35-2 is a single channel version, only half of the circuitry is needed. As a result, the main board is slightly shorter than that in the PPS 2322 and there is no auxiliary power riser board. The main filtering cap is re-located to the main board thanks to the freed up space.

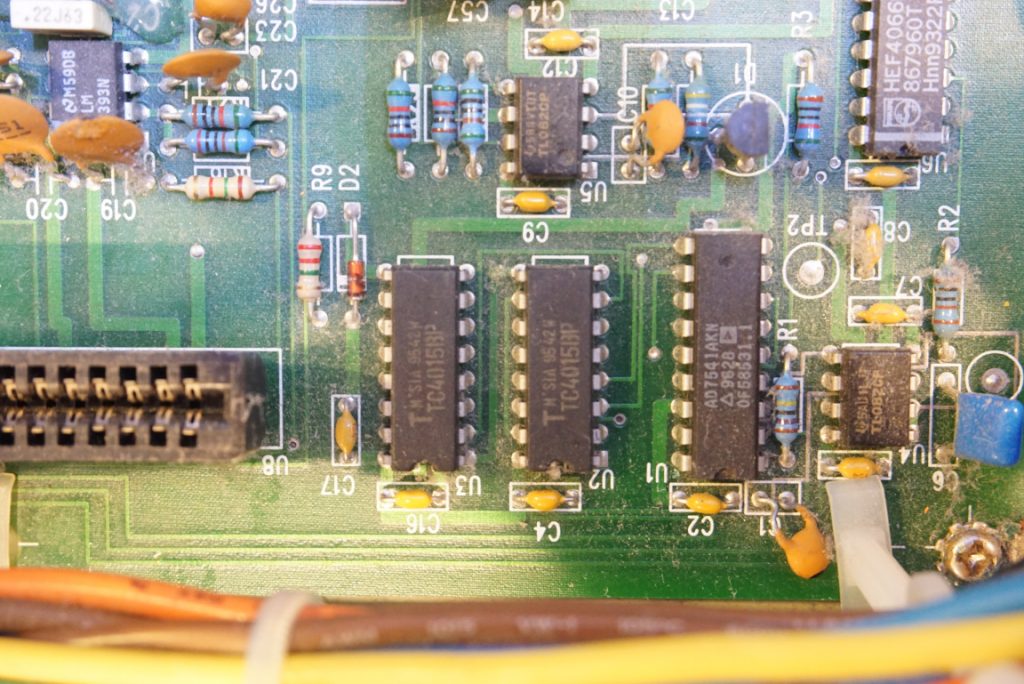

If you recall, in my teardown of the PPS 2322, three chips next to the process board socket had their markings sanded off. In this power supply though we can clearly see what these three chips are in the picture to the right below.

The two 16 pin DIP ICs are TC4015, dual 4-stage static shift registers. And the 18 pin IC to the right is an Analog Devices’ AD7541 12-Bit monolithic multiplying digital to analog converter chip (DAC).

There are a couple of bodged on resistors on the main board as can be seen below, looks like they are part of the differential input for the sensing circuitry.

In the image to the left below, you can again see the toroidal power transformer and behind which you can also see the single line LCD board.

Because remote sensing is supported from the front panel, you can see the ferrite beads on the wiring at the front terminals. These ferrite beads are used to reduce the noise induced on the sensing terminals and thus improve the power supply transient performance.

Below is a video of this teardown:

Amrel PPS 35-2 Firmware Download

AmrelPPS25-2-7.00.zipMD5: f4984ed12432c671acd08b795dc05925